Products Catalogs & Keywords:

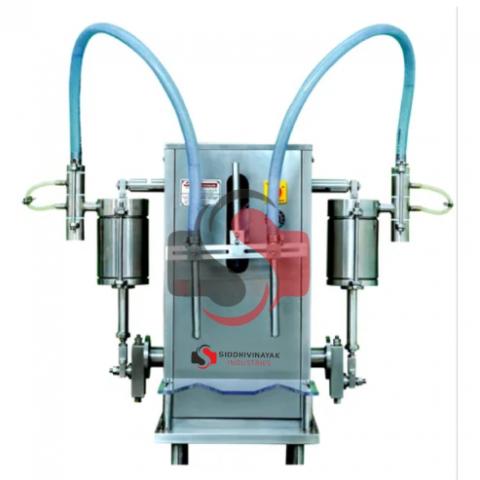

Semi Automatic Volumetric Liquid Filling Machines provide affordable and efficient filling for a range of applications. They utilize a piston pumping system to accurately measure and dispense liquids into containers.

The operator loads empty containers into the filling station and initiates the filling cycle. The machine then precisely fills each container to the preset volume using volumetric piston pumps. Fill volumes are highly accurate and consistent from one container to the next.

These versatile machines can fill a variety of container materials, shapes and sizes. Quick changeover parts allow switching between container types to fill bottles, jars, vials, tubes and more. They can handle a range of liquid viscosities from low viscosity solvents to thicker oils or lotions.

Most semi automatic fillers have a small footprint to conserve benchtop space. They have an LCD display for easy programming of fill parameters like time, volume, speed and more. Recipe storage allows fast changeover between products.

Additional features may include drip-free, tip-touch filling nozzles, container holders, and conveyors to automate container loading and unloading. Some advanced models offer weight checking to verify fill accuracy.

Semi Automatic Fillers provide an affordable solution for medium batch size filling with more flexibility and precision than manual filling. They are suitable for pilot plant operations, small batch manufacturing, laboratories, universities, and other applications not requiring full automation.

Semi automatic filling machines maintain fill accuracy without the added cost and complexity of fully automatic fillers. They give the operator greater control over the filling process while still improving consistency and efficiency over manual filling methods.

With their versatility, precision, and easy operation, semi automatic volumetric liquid fillers are an excellent option for liquid and low viscosity products that require accurate, repeatable fill levels without the need for high volume automated filling lines.